Introduction

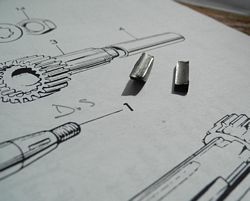

(Click Thumbnails to Enlarge)

Here are some photos of the Bonnie during the 2015 Winter tear-down.

Goals

In addition to a thorough cleaning/polishing and annual check-up, this winter's tear-down has two major goals.

Electrical Gremlin

The first goal is to banish the pestiferous electrical gremlin that plagued the Bonnie during much of last summer. Although I learned how to temporarily dispatch the gremlin (a gentle tug on the wiring harness where it looped out from between the frame and the gas tank on its way to the headlight shell and ignition switch), I could never pin down the exact location and cause of it.

Considering how I often ride in relatively remote areas and that I do not own a cellphone, the prudent thing is to expunge the gremlin once and for all with entirely new wiring.

I replaced the original wiring harness in 2006 with a cloth-covered reproduction from British Wiring and I was quite satisfied with the quality. However, due to changes I had made, such as relocation of the condensers and zenner diode, none of the stock wiring harness configurations were an exact fit and I had to make modifications to the new one.

In the interim I eliminated the condensers when I installed a Pazon CDI, and have now also acquired a Podtronics regulator to replace the zenner diode and selenium rectifier. All the older components functioned perfectly as far as I know, but nothing lasts forever and in the interest of reliability I decided it would be expedient to upgrade them.

Furthermore, I don't run the Bonnie with the oil pressure switch or turn signals and I have integrated the handlebar dip switch into the headlamp shell's Lucas 35710 lighting switch.

All things considered, a standard wiring harness didn't make too much sense, so I have elected to create my own custom wiring system.

Compared to the stock electrical wiring system the simplified custom wiring should provide highly reliable service.

Selecting First Gear

My second goal is to eliminate the Bonnie's tendency to pop out of first gear during the first few minutes of operation.

This problem began surfacing sporadically several years ago and had gotten progressively worse. It has now reached the point where it occurs regularly at the start of each day. Although it always disappears after three or four minutes of warm up, and never appears again until the next day's cold start, whatever the cause it can only get worse so I want to eliminate it while it is still only an annoyance.

Since the transmission is stripped and the outer gearbox cover is removed, it makes good sense at 65,000 miles to inspect all gearbox components. Pulling out all the gears is something I probably would not consider doing myself. Heck, I wouldn't even pull out one or two!

But since the most knowledgeable and accomplished Triumph/BritIron guy around has offered to guide me, I am ready to go where no amateur mechnic like me has dared to go before. At least, not soberly. More pics to come. Of course.

Issues

The only major issue encountered (so far) was removal of the clutch center. On two separate occaisions previously I managed this with no difficulty using the proper extraction tool. My first attempt this time only succeeded in stripping the outside threads of the extractor.

Had not a clue what to do next.

However, acting upon advice from reliable and experienced guys, I threaded the new tool into the threads inside the clutch center, tightened the extraction bolt (bears against the end of the mainshaft) enough to pre-load a force between it and the end of the mainshaft, and then gave the bolt a good blow with a soft, heavy brass hammer. Satisfying. But no luck.

Next, with the extraction tool still installed and pre-loaded as before, I tried gently tapping laterally against the sides of the clutch center with an aluminum drift. Followed by a couple more shots of brass hammer. Still no luck.

What finally succeeded was the air wrench set to its weakest force, gently hammering away on the extraction bolt for possibly an hour, or at least 15 or 20 seconds during which I got to wonder if I was purely and simply destroying threads of clutch center and tool alike.

After the clutch center finally came off the mainshaft, the key between them was taken out in two pieces, one from the shaft and the other from the hub.