Clutch Tool

By Hans MullerWDM20 58764

May 2007

The one-spring BSA clutch is a PITA to dismantle (if you are not VERY careful, the notched nut and spring will say DOIIING..!! and get into orbit in your garage) and to assemble again.

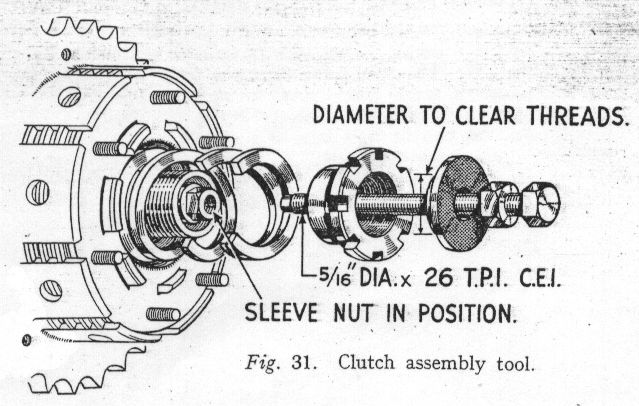

The Motorcycling articles show a so-called simple method (pic. 1) to compress the spring, and allow the notched nut to engage the thread, with the clutch in place. You need a 5/16"x 26tpi bolt or threaded rod, a large enough washer and a nut. I tried this method, and it was a bit disappointing; while dismantling it allows the nut to be unscrewed in a controlled way, but during assembling it is difficult to find and engage the thread.

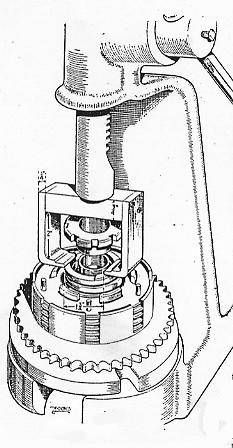

A much easier way is when you can work with the clutch removed from the bike; with a special tool you can compress the spring with a bench- or a drill press. The U-tool shown (pic. 2) however has a major flaw; you cannot use it for dismantling and when assembling you may easily engage the nut on a few threads, but then you will have to slide the U-tool sideways out, and finish to screw on the nut against the spring force.

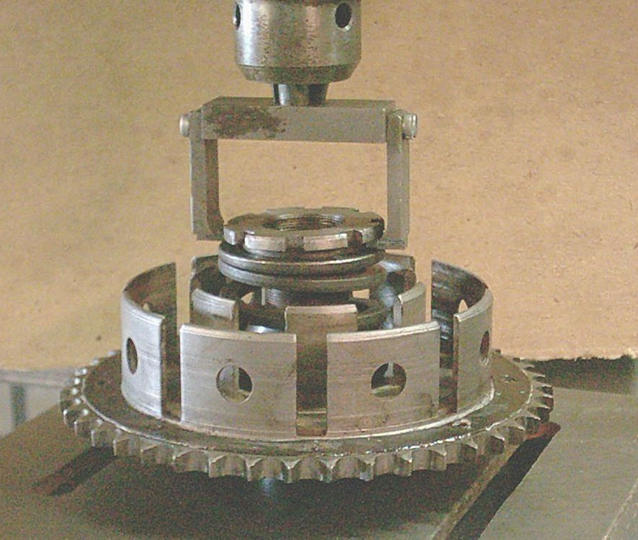

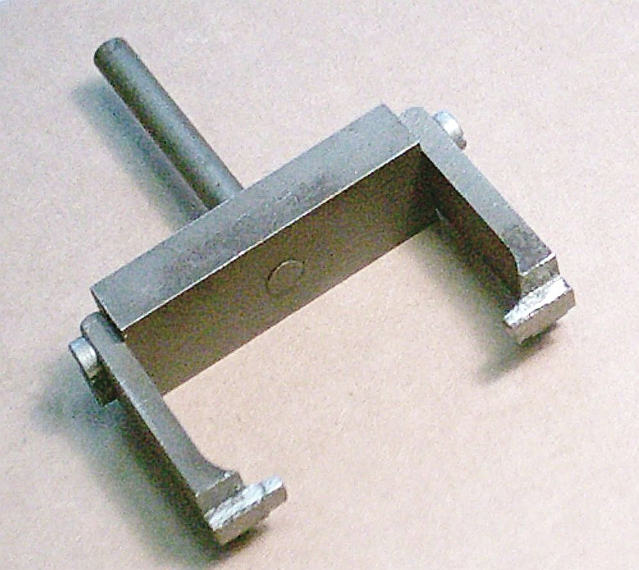

I modified the U-tool in such a way that the two prongs will pass through the notches in the nut. You can now compress the spring to its limit, engage and screw on the nut, and get the tool out again without any problem (pic. 3 and 4).

Since a drill press is not always available in the field, I am thinking about a portable version, using the threaded rod in the clutch nut and the U-tool.

Final suggestion: use a suitable hook spanner! That will make the work much easier, and will not damage the nut.