How to Cut (leather) Corners

By Hans MullerWDM20 58764

May 2007

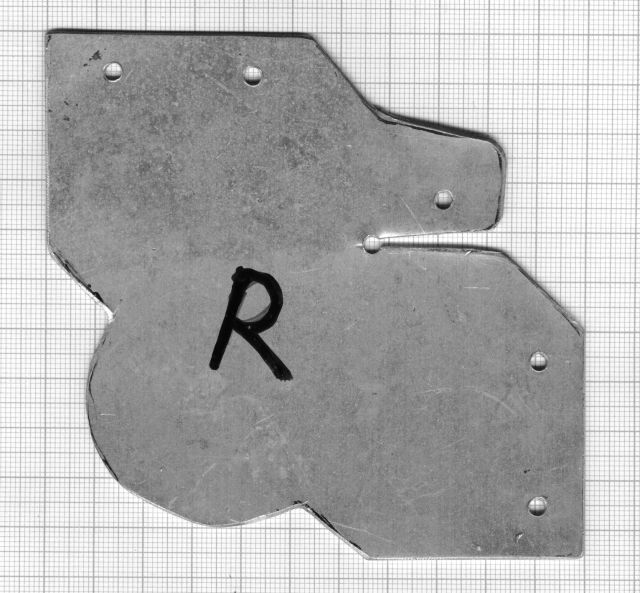

- Copy the template from the sketch (1 cm squares) (Photo 1). For a single

corner, you can use thick paper or cardboard; if you want make more, a

piece of thin aluminium or zinc is better.

Photo 1. Template.

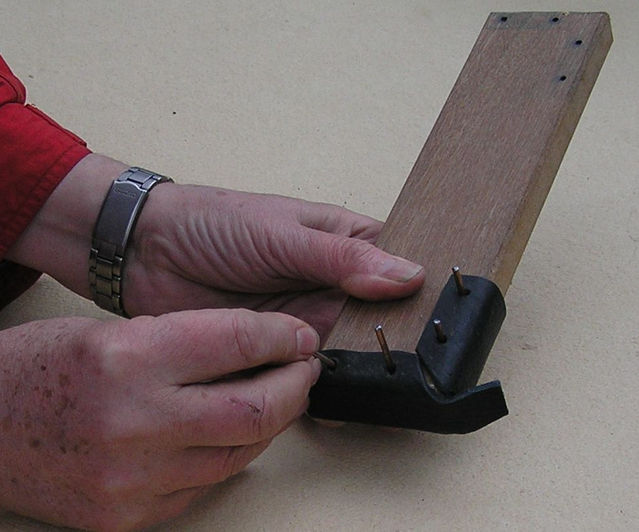

- Make a mould from a piece of (hard) wood, thick 23 mm and 65 mm wide;

slightly round the corners. Drill 3.1 mm holes as can be seen on the

pictures, corresponding with the holes in the steel reinforcing corners.

Also make at least 4 steel pins fitting the holes; 3 mm welding rod will

do. (Photo 2)

Photo 2. Hardwood mold.

- Find some saddle leather, 2 - 3 mm thick; black or brown will do. Be careful with old leather from briefcases etc..; it will easily tear or break.

- Cut the leather according to the template; there is a difference

between the left and the right corner ones! Punch out the 4 holes with

a 3 mm hollow punch. (Photo 3)

Photo 3. Cut and punch leather pieces.

- Soak the leather for 24 hrs in water.

- Insert two pins in the mould, put the leather on these pins, and fold around the mould. Then, insert the two other pins. With 3 mm leather this will require some persuasion! (See photo 2).

- Let the leather dry for 24 hrs; do NOT use heat.

- Now put the corner in place, temporarily fixing it with 3 mm

screws and with the steel reinforcing corners in place. (Photos 5 and 6).

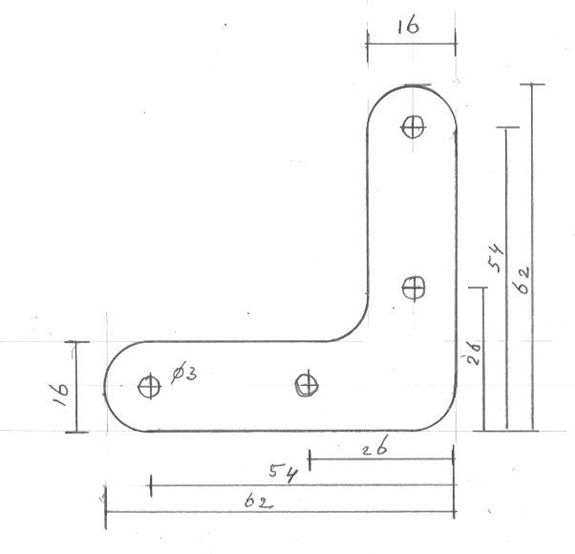

If you don't have these corners, you will have to make them of thin

(0.8 - 1 mm) sheet steel, and treat them with any anti-rust product;

I used zinc coating from a rattle can. (Photo 10)

Photo 10.

- Put the bag on the frame, and mark the place of the press fastener

using a small hammer. (Photo 7). Remove the corner, and put in a press

fastener; if you don't have the tools for that, go and see your

friendly shoemaker.

Photo 7.

- Attach the corner again with the 3 mm screws, and using 3mm flat

head copper rivets and washers, replace one by one the 3 mm screws

(photo 8).

Photo 8.

If the rivets are too long, cut them off at about 2 mm above the washer. Avoid the normal hollow rivets; they will not withstand the rough life on a M20 bike, unless they are of the stainless steel variety (photo 9).

Photo 9. Rivets.

- Use a split rivet to fix the small corner flap.

- Now finish with some leather oil or wax.